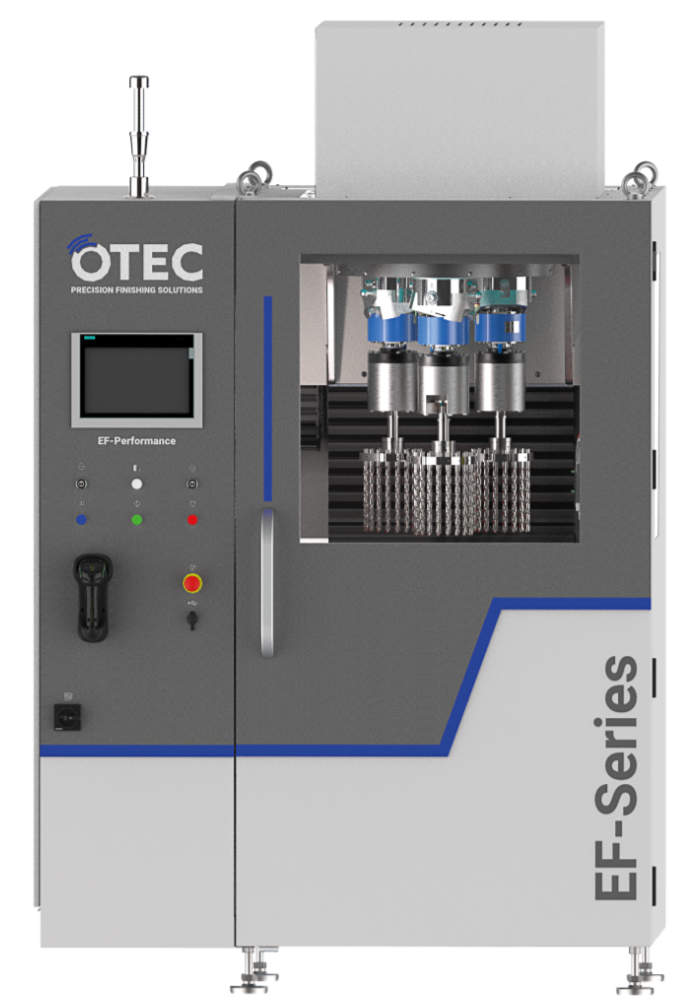

Electro-Finishing - Takes Surfaces To a New Gloss Level

OTEC’s latest-generation electro-finishing machine takes surface processing of engineered components to a new gloss level.

Particularly for complex geometries and 3D printed parts, OTEC electro-finishing technology is the perfect complement to other mass finishing processes. Delivering high-gloss results even in hard-to-reach areas in components made from stainless steel, steel, brass, silver, cobalt chrome and titanium.

The OTEC EF machine uses special polymer particles suspended in an ionically conductive liquid. Unlike conventional electrochemical polishing, this technology involves the workpieces moving (rotating) through the abrasive, ensuring that it circulates uniformly around the part.

The media moves around in the electrolytic (conductive) liquid. Voltage between the cathode and anode ensures that the particles keep moving. The particles make contact with the metal ions on the workpiece surface produced by the voltage (roughness peaks) and removes them. The metal surface of the workpiece is gradually smoothed to perfection.

Call Fintek 01706 825819 or enquire here

EF Performance

- Low mechanical stress on workpieces

- No bending or breakage

- Uniform smoothing and minimal edge abrasion

- No micro-scratches

- No impact on microstructure

- Reaches deep areas of the workpiece, even with complex geometries

- Minimal media jamming thanks to tiny spherical finishing particles and/or pure liquid

- Achieves roughness values as low as Ra 0.01μm

- Low per-component energy consumption

- Custom process definition with efficient parameters

- Suitable for use by non-specialist personnel as it is not irritating to the skin

Download:

Electro-Finishing Brochure

EF Series Brochure

For lower processing requirements OTEC produce smaller electro finishing machines, developed for the jewellery industry.

Other Electro-Finishing Machines

Going Beyond

In addition to OTEC electro finishing machines, Fintek supply the full range of CF disc, EF electro, DF drag and SF stream finishing machines. From bench-top to series production fully automated and robot assisted, find out more.

Click the buttons below: