OTEC EF Range for Fast Precise Electro-finishing of Jewellery Pieces

Fintek are pleased to offer world renowned UK fine precious metal artisans, jewellery and watch makers, the EF range of electropolishing machines from OTEC Präzisionsfinish GmbH. These are designed to minimise the manual work required in finishing fine jewellery and horological pieces.

Whatever you are creating - bracelets, ear rings, bangles, pendants, rings and necklaces in yellow, red and white gold, silver, brass and stainless steel – there is an EF machine to make your work flow easier. Delicate and intricate pieces of jewellery with complex geometries can all benefit from perfect process reliability, processing even in the smallest of corners, and extremely short process times. From low to high-volume production, choose an OTEC EF machine.

Call Fintek 01706 825819 or enquire here

|

OTEC's beutifully illustrated guide to high gloss finishing for the jewelllery industry |

EF Nova

- Ultra-compact table-top electro finishing machine

- Intuitive control panel - with guide through menue

- 8 pre-installed programmes - making it easy for beginners

- Plug-and-play-system

- Intelligent media container recognition

- Special holders available for individual workpieces

- Processes up to 6 rings simultaneously (excp. white gold-palladium – up to 2 rings)

- Current – max. 5A (otherwise process will be stopped automatically)

- Pulse module (i.e. white gold-palladium can be processed)

- Applicable only for EF liquids

- Only 10-30 minutes processing time per cycle

- Up to 100% gold recovery – no material loss

EF Smart S

- Suitable for cast and 3D printed jewellery

- Finishes stone-set jewellery as well as intricate geometries

- Process gold, silver, brass and copper

- Easy precious metal recovery via deposition on cathodes

- Easy-to-program the direction of rotation, voltage, processing time and speed via touch screen. Precise and repeatable

- Process container cover with 4 holders, each for 4 jewellery pieces (16 processable in total)

- Can be controlled by mobile phone application

- Small desktop footprint - 450 x 610 x 605 mm

- Finishing with glass beads also an option

PDF Flyer for EF Smart S

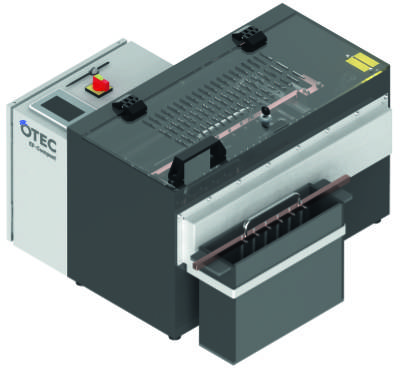

EF Compact

- Machine processing replaces up to 90% of time-consuming pre-polishing

- Cyanide-free abrasives with no aggressive acids

- Reproducible and fast results in a process time of just 10-20 minutes

- Easy recovery of abraded gold through filtration of the electrolyte and separation at the cathodes

- Touch panel for easy programmable parameter management system

- Completely cyanide-free process

PDF Flyer for EF Compact

EF Flex

- Machine processing replaces up to 90% of time-consuming pre-polishing and filing

- Modular design is ideal for increasing capacity as your production needs increase

- Comes with one tank and easily scales-up by adding up to two more process tanks

- Each tank can process up to 40 jewellery pieces at the same time.

- Filter unit absorbs particles

- Easy recovery of abraded gold through filtration of the electrolyte and separation at the cathodes

- Touch panel for easy programmable parameter management system

- USB port for software updates

- Completely cyanide-free process

PDF Flyer for the EF Flex

OTEC ECO Maxi and ECO Mini – Table-top Disc Finishing for Jewellery Polishing

For jewellery makers, OTEC have also developed compact versions of their ground-breaking industrial CF disc finishing machines. These are the ECO Maxi and ECO Mini, both table-top, easy to use, units.

ECO Maxi

- Low investment, low space requirement – table-top

- Three processes in one unit – magnetic, wet and dry polishing

- Fine polishing granulate ensures material removal in the micro range

- Diamonds, zirconia or pearls in their settings are not damaged

ECO Mini

- Tiny footprint even on a table-top

- Quickly restores tarnished and worn jewellery to showcase standard

- Available in wet and dry versions

- Built-in timer

Medium to Large Scale Jewellery Production

For more robust pieces or larger processing quantities, whether made from precious or non-precious metals, Fintek are able to offer the OTEC CF disc and DF drag ranges of finishing machines. These come in variants from single to large multi-bowl systems and also have optional separation units.

CF Disc Finishing

- Ideal for medium to large scale jewellery and decorative piece manufacturers.

- Modular: 1-6 drum

- 7.5 inch colour touch panel – up to 1000 storable programmes

- Wet and dry finishing

- Integrated options for remote machine maintenance and control